Achieving exceptional weld quality in structural applications requires mastery of every component in the welding process. Among these components, ferrules stand out as a fundamental element that transforms arc stud welding from a basic joining method into a precision engineering process. Let’s explore why these ceramic components play such a vital role in achieving superior welding results.

The Science Behind Ferrule Technology

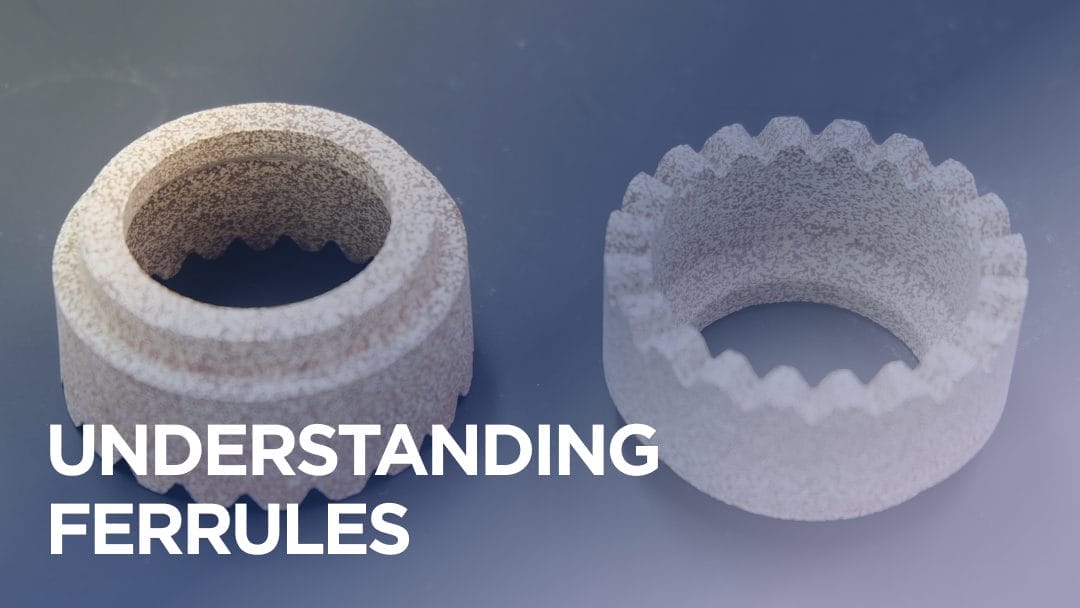

At its core, a ferrule serves as a precision-engineered ceramic shield that creates an optimal environment for weld formation. When the arc is initiated between the stud and base material, the ferrule contains and directs both the molten metal and the arc energy, much like a master craftsman’s tools guide their work. This controlled environment allows for the perfect fusion of materials, ensuring structural integrity that can withstand decades of stress.

Critical Functions in the Welding Process

Thermal Management and Distribution

The ferrule’s ceramic composition performs several crucial functions during the welding cycle:

The ceramic material creates a contained space where temperatures can reach optimal levels for complete fusion. This containment ensures that heat spreads evenly through the weld zone, similar to how a well-designed oven maintains consistent temperatures for perfect baking results. Through this careful thermal management, the ferrule helps achieve complete penetration and uniform bonding across the entire weld surface.

Protecting Weld Integrity

In challenging welding positions, particularly vertical and overhead applications, ferrules become even more critical. They act like a protective shield that:

The ceramic barrier prevents molten metal from shifting or dripping away from the weld zone, much like a dam controls water flow. This control is especially crucial in overhead welding, where gravity works against the welding process. By maintaining proper metal placement throughout the weld cycle, ferrules ensure consistent strength regardless of welding position.

Quality and Appearance Benefits

Beyond their structural contributions, ferrules significantly impact the final appearance and efficiency of the welding process:

The controlled environment created by the ferrule naturally contains spatter and directs the cooling process, resulting in welds that require minimal cleaning or finishing. This efficiency saves valuable production time while ensuring a professional appearance that meets the highest industry standards.

Applications Requiring Ferrule Usage

Understanding when ferrules are necessary helps optimize both weld quality and operational efficiency:

Heavy-Duty Applications

Structural steel construction and heavy machinery manufacturing demand ferrules because:

The increased mass of larger studs and thicker base materials requires precise control of the larger molten metal pool. The ferrule provides the necessary containment and direction to ensure complete fusion across the entire weld interface, much like how a foundry uses molds to control larger metal castings.

High-Stress Environments

In applications where welds must withstand significant loads or environmental stresses, ferrules become indispensable because:

They enable the formation of precisely controlled weld profiles that distribute stress evenly across the joint. This stress distribution is similar to how a well-designed bridge distributes traffic loads across its support structure.

Optimizing Your Welding Operations

Selecting the right ferrule for your specific application involves considering several factors:

- Material thickness and composition

- Stud size and geometry

- Environmental conditions

- Load requirements

- Quality standards

Expert Support for Your Welding Needs

At Davis Stud Welding, we understand that each project presents unique challenges and requirements. Our team of welding specialists can help you:

- Select optimal ferrule types for your applications

- Develop efficient welding procedures

- Ensure compliance with quality standards

- Maximize operational efficiency

Contact us to discuss how proper ferrule selection and usage can enhance your welding operations. Let our expertise guide you toward achieving exceptional weld quality in every project.